Once Andy had determined the brew was ready to be bottled, he started work cleaning bottles. We had saved several and he had gotten several boxes of used ones from his brother as well. We did buy one box of new bottles cause they have fancy tops that we both really like. He had to soak all the used bottles and peel all the labels off. Then they had to soak in a sanitizer solution and be set up to dry a bit. Everything the beer mix touched, buckets, tubes, connectors, siphons, had to be sanitized and be untouched by us or any surface not covered in sanitizer solution. This was a bit of a frustration on Andy's part, but he was militant about it. He wanted his brew to turn out perfect, even tho he still worried about it being contaminated and getting infected. Who knew beer could get an infection? Basically it means that the beer got bacteria in it and makes it rotten, hence the need to sanitize everything.

|

| Soaking bottles in sanitizer |

|

| The dishwasher came in very handy as a drying rack |

|

| Bottling bucket is ready to go, just needs a hose on it |

Once the beer had been poured into the bottling bucket, a sample was removed to be tested for taste and alcohol content. This is where we would find out for sure if it had gotten an infection.

|

| Color looks good! |

We both tentatively took a sip. I have to say, at room temperature and non carbonated, it actually tasted pretty damn good. Can't wait to taste it ice cold and carbonated. Andy kept a big grin on his face for quite a while and he tested the alcohol at about 5%. Not too shabby for a first shot at brewing! He mixed a sugar solution into the bucket that will force the beer to carbonate in the bottle and we got to work bottling it.

|

This thing is cool, the end has a shut off. You put it in the

bottle, but it doesn't start filling til you press it on the

bottom, then it stops when you pull it up! |

|

| These are the fancy bottles we bought new. Love the tops! |

|

This is the fancy capper tool I used for the rest of the

bottles. It was pretty fun and easy to use. |

|

| 39 bottles total - 6 22oz, 15 16oz, and 18 12oz bottles |

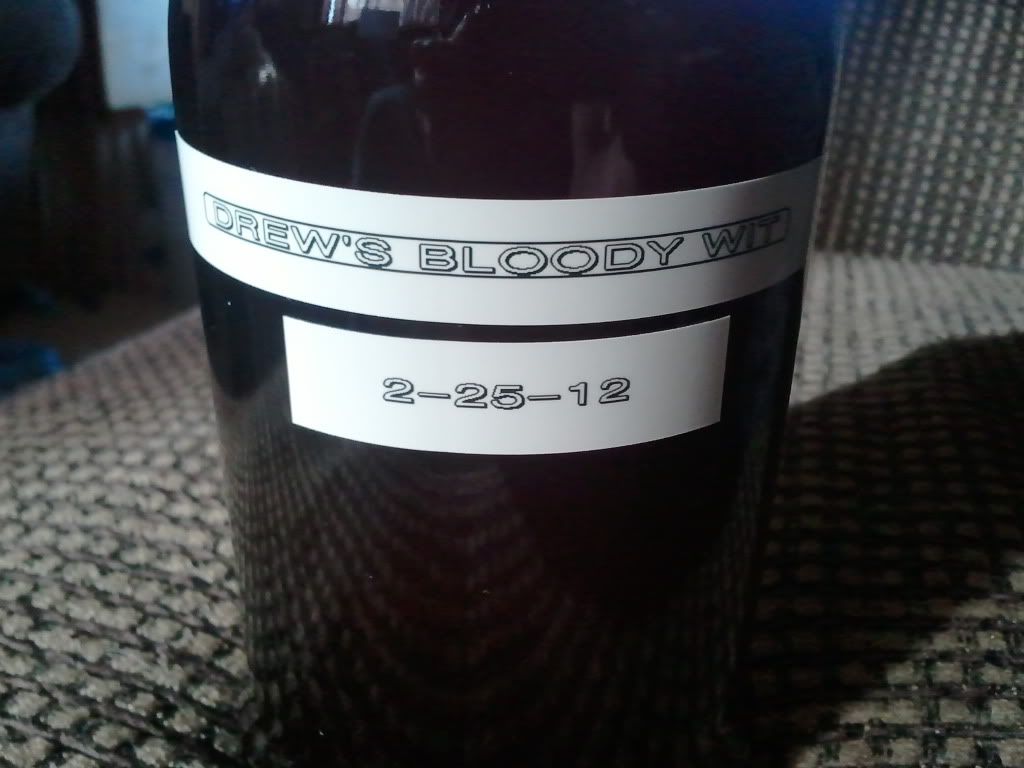

I decided to get fancy and finally put our label maker to use. I ran out of tape so couldn't label them all, but I did get all the fancy bottles labeled. The rest I just wrote the date on the cap with a sharpie.

Now we get to stare at 39 bottles back at the end of the hall and wait for them to carbonate. I covered them with old sheets as a precaution, however. Andy told me that sometimes bottles have been known to explode during the carbonation process from too much pressure build up. I figure the sheets will at least keep it somewhat contained if one happened to get mad and blow it's top.

No comments:

Post a Comment